Preparing Pipe for Ordinate Lengths EXAMPLE NO. Applying Ordinate Lengths to Pipe (Radial Cuts) EXAMPLE NO. Laying Out Angles EXAMPLE NO. This part is contain the most recent and. Cut back reading from the formula.

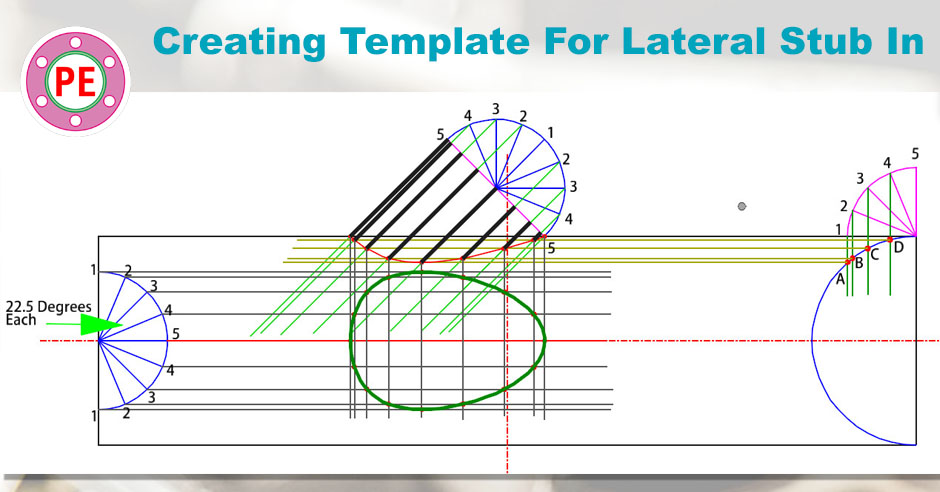

If a torch is use always remember to cut with the kerf of the torch on the outside edge of the cutting lines. Draw a horizontal line of this length. Divide this line into equal parts as we have divided header and branch pipes into equal parts of 22.

Tube and Pipe Notching Calculator – Full Scale Printable Templates If Cut Tube Wall Thick is larger than the cut fits to the inside diameter of the tube, making a notch for welding. For a snug fit at the outside of the tube, enter Cut Tube Wall Thick and grind inside of tube to fit. A saddle cut is a way of cutting one pipe to match the outside curved surface of another pipe. The resulting pattern will look like the profile of a saddle, a curved center section that goes over the second pipe and two curved sections that extend down on either side. The pipe is cut such that its end aligns with the inside surface of the header pipe such that no restriction of flow will occur inside the header pipe.

Inside Header Pipe : The branch pipe extends all the way through the wall of the header pipe and ends at the centerline of the header pipe. No cut template is generated for the branch pipe. An equal tee-piece is where the pipe intersecting the main header pipe is the same diameter as the header pipe. Generally the mitre line of an equal tee-piece will intersect as far as the centre line of the main header pipe. Pipefitters Math Reference Chart – as PDF File (. pdf ), Text File (.txt) or read online for free.

The common formula for calculating the loss of head due to friction is Darcy’s one. Under torquing the bolts may result in lower pressure retention capabilities, lower bend load capabilities, joint leakage and pipe joint separation. Pipe joint separation may result in significant property damage and serious injury. The Sweepolet is the recommended branch connection for Class I (critical service) nuclear piping.

THE WELDOLET PROVIDES 1 PIPE STRENGTH FOR ALL SIZES, WEIGHTS AND SCHEDULES. A o = external pipe surface area (ft per ft pipe ) Internal Pipe Surface. Internal pipe or tube surface per ft of length can be expressed as. Transverse internal area can be expressed as. Or check Plot Points to calculate and display lateral measurements at set increments around the pipe , to mark the cut line for the miter.

An example of radial-line development is given in Fig. The dimensions required to make the development are the circumference of the base and the slant height of the cone. Pipe attachment welds shall be in accordance with the Code.

For carbon steel and ferrous pipe materials through chrome operating between -29ºC (-20°F) and 260ºC (500°F), pipe support attachment material shall be carbon steel. Depending on the pipe size, a half round file can be used to remove any burrs created when the land is ground on to the end of the pipe. Welding the Root Pass Before beginning to weld the pipe , the procedure should be checked to assure that the correct electrode is being used. This includes the diameter and the classification of the electrode.

A second cut shall be performed to obtain the required weld bevel (per WPS). Cut hole using scribe line as a guide. Cut should be parallel to branch pipe axis. Use outer-most edge as template, scribe onto header pipe.

In this work we have studies head loss in T-junction of pipes with various inlet velocities, head loss in T-junction of pipes when the angle of the junction is slightly different from degrees and T-junction with different area of cross-section of the main pipe and branch pipe. The rule is demonstrated in Figure on the next page. The program does not produce patterns for multiple branch to mainlines or any configuration other than single pipe cutting or one branch to mainline.

Find the cutting tool for your specific task andget instant cutting data recommendations.