Cut and use template to mark and cut sheet to fit pipe at 45° angle. Select Angle Increment and hit Full Set to generate and print a full set of oval templates for currently entered pipe diameter. To find pipe end shape (not hole in sheet), enter for Sheet Thick. What is the best angle for a saw to cut a pipe? How to layout a pipe saddle cut?

How many degrees are in a small pipe?

Measure up your first vertical line the distance of one half the diameter of the top pipe plus. Use this intersection as the center point and draw a circle to represent the inner edge of the upper pipe with a diameter of 21. I am having a bit of trouble with cutting angles when building gates and trusses.

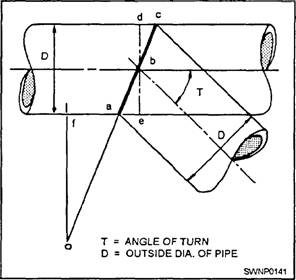

I have specific wraps for 45. For larger size pipes and where pressure drop in elbow is not critical, miters can be used instead of standards elbows. Here is formula to calculate required dimensions to fabricate miter from pipe. In the figure above, dotted lines are where the pipe should be cut.

When cutting pvc pipe must the cut always be square relative to the angle of the pipe or relative to what you want the rest of the pipe to be parallel to?

Suppose the diameter of the pipe is d units and the pipe is sliced by a plane in inclination φ degrees, in your case 1degrees. To cut a simple 45° on a 3. Chalk a line around the pipe. Secure pipe so it cannot rotate. You should have parallel lines at the same. A o = external pipe surface area (ft per ft pipe ) Internal Pipe Surface.

Internal pipe or tube surface per ft of length can be expressed as. Based on the isometric drawing all pipe lgth will be deducted by the take off of the elbows. Transverse internal area can be expressed as. For degrees elbow and example OD.

It will allow you to keep your cuts straight. Other types of cutting , such as using a tube cutter, will inherently keep the cut straight. How can I single out the pipe for cutting ? Don’t Forget the People Factor. Despite tremendous functionality, technology alone does not minimize the role of the programmer or operator.

A metal- cutting guide set can help you easily perform 22-, 45- and 90-degree angle cuts and saddle cuts on metal pipe. Pick up a gas saver device that can automatically shut off gas on welding and brazing production projects.

In your case where the plane that slices the pipe has an inclination of 1o this is. Pipe cutting techniques at an angle. So, hoses made of polypropylene or thin copper are easier and easier to cut than thick-walled steel pipes. Cutting cast iron pipe with an angle grinder is super easy. You really just need to mark the pipework with some chalk or even a crayon and fit yourself with the appropriate PPE gear.

Use a grease pencil to mark the waterline. Mathematical way: If you were to unroll the pipe , you would find that the cut would be a sine wave. So if you draw a sine wave of the right amplitude and wavelength on a piece of paper, you can wrap it around the pipe to show where to cut it. Pipe beveling is the process where an angle is formed between the edge of the end of a pipe or tube and a plane perpendicular to the surface. A standard pipe bevel angle for welding is 37.

Other angles and special forms such as J-Bevels can also be produced on the ends of pipe or tube using automatic beveling machines. Calculate elbow center to end dimension for inch nominal pipe diameter elbow at degree angle , cut from degree LR elbow. Liquid in cylindrical pipe or tank on an incline (tippe slante slope leaning). Register to enable Calculate button.

Demonstration mode for ∅=o and D=m (cookies must be enabled). Enter the arccosine of 0. So you have found all the angles for the shelf support, with angle c equaling degrees, angle b equaling 33. My recollection is a straight cut could build up harmomics (standing waves) and reduce capacity.

If you notice, organ pipes , and many automobile exhaust pipes are cut at an angle.