Better quality and service. What does the name tie mean? A form tie is an accessory used in formwork , used to hold the concrete wall forms firmly against the lateral pressure of freshly placed plastic concrete.

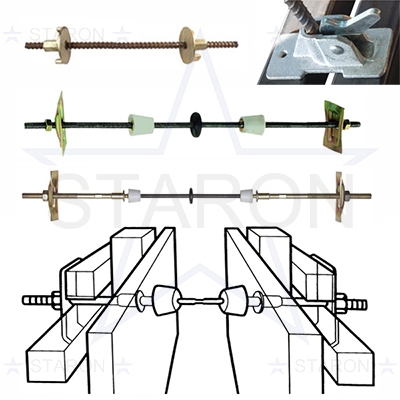

They maintain equal space between the forms which in uniform thickness of walls. A form tie contains two parts namely internal tension member and external holding device. Self-Centering” Loop Ties set the wall thickness by pressing up against inside (face) of the wood forms with cones, allowing a clean break-back during stripping.

The wedge tie (WT ) is a form tie that secures concrete forms in place while the concrete is poured. It easily installs between form boards and accurately spaces the forms. Several models are available for varying wall thickness and types of form boards. Ellis manufactures a wide array of form ties for each of their forming systems.

Whether your job requires ties with water seals or cones, or just a standard snap tie, Ellis has you covered. For complex, difficult or unusual builds, Ellis can custom manufacture form ties for any job. DYWIDAG-Systems International (DSI). We do not only value the personal relationship with our customers, but also provide 24-service.

RSupply has great prices on snap ties and wedges you need for a variety of concrete form work to build retaining walls and landscaping borders of all sizes.

The Simpson Strong-Tie WT-Wedge Form Ties are designed for low foundation wall applications with a width. There are various systems you can use to create the form system you require depending on your needs. Wall thickness from 6. Snap ties make the installation of concrete formwork and the subsequent removal extremely easy and efficient.

Dedicated to quality, ease of use and customer satisfaction, we are a leader in the industry for residential and light commercial construction. PATCHING, BONDING AND GROUT. The FT form tie and WG wedge system allows concrete wall forms to be made from 2x nominal form lumber by accurately securing them in place while the concrete is poured. This product is intended for a maximum wall height of 4-feet. FT – Connect 1x and 2x nominal form lumber in low foundation walls up to 4-feet high.

Product Overview Concrete form Snap ties are basically tension members. They are designed to resist the lateral pressure of fresh concrete on vertical forms. When properly fitted with cones or other they hold the wall forms at the proper distance to create the desired concrete wall thickness. Snap Ties are used to vertically form concrete walls that can have a wide variety of widths and heights.

Aluminum Forms , Ties and Accessories. Silver Bullet Base Pin. Use Z- Form Ties on jobs that have a offset in the wall, from the straight line, along with inside corners. The offset and the corners are constants and cannot be changed.

These, combined with the wall thickness variable, control the finished shape of the tie.

Available in Full and Nominal. On the interior, next to an actual cast-in-place concrete wall, is a partition of plaster wallboar with a pattern simulating concrete ties. As often happens in architecture, constructional necessity has mutated into pure decoration. For more than years, Ellis Formwork Manufacturing has led the way in product innovation and cost savings in the poured-in-place concrete construction industry. We proudly produce the first and only, heavy duty fiberglass loop tie for steel-framed modular forms.

The tie functions exactly the same as a steel loop tie with respect to installation and strength, but it will never rust in the wall and it eliminates the need for patching. This system provides a temporary frame work that you attach your plywoo using screws to hold it in place until the concrete has cured. After which you simply unscrew your plywood which may be used again for future projects. With the SPIDER TIE system you can form any shape wall in a fraction of the time that’s required with all other systems.

Subsidiary of OKABE Co. Our parent company has fully owned manufacturing facilities. ELITE Forms and Accessories: Elite panels. SITE BUILT: Fast cone coil ties. CHEMICALS: greenkote.